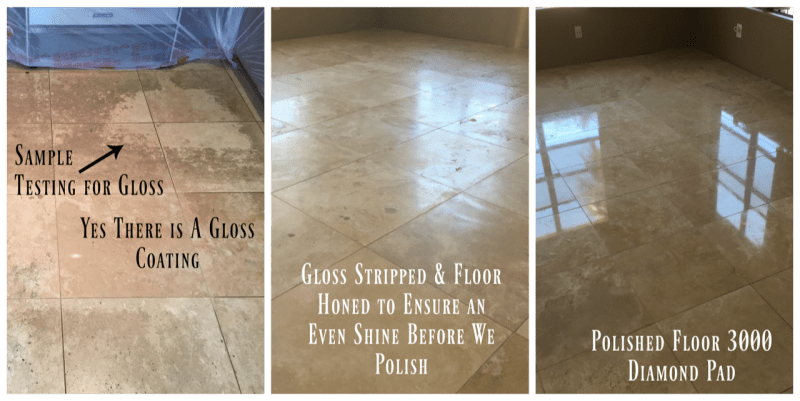

High-gloss diamond polishing for travertine floors in Scottsdale, AZ

The first way, and one that WE DO NOT RECOMMEND, is through a topical coating or gloss sealer. These topical coatings are sold at all the big box stores and have a white milky appearance. Gloss sealers have their uses but shining up travertine floors is not one of them. These off the shelf sealers, and even some cleaning products, will leave behind a waxy build-up that grabs dirt and dulls your floor. Steer clear of anything that says it will “shine” your floor. The right way to “shine” your floor is through diamond embedded pads and heavy mechanical cleaning equipment.

The Process

An initial assessment will be made to determine the current condition of the floor. What is the shine level? Does the floor appear to have a coating? Are there scratches, etch marks, cracks, or holes?

While we make every effort possible to determine whether or not a floor has a topical coating, we cannot guarantee that one does not exist. Frequently the cause of waxy buildup on natural stone floors can be traced to the use of commercially sold “clean & shine” products containing wax as well as improper use and overuse of sealer. Overtime, waxy build-up from these fake, “shine in a bottle”, cleaning products begin to dull the floor giving it a grayish appearance.

So, your floor has a topical coating

We are incredibly passionate about refinishing stone and returning it to its former glory. One of the reasons we love stone so much is that stone floors are forever. However, this material is also very versatile, and this means it’s able to take on many appearances. This allows us to make changes to meet modern trends. It’s very common for customers to request more shine and color, though we can also help you reduce the amount of shine and color in your stone if you require. We can also help if you need a new grout color. We love the challenge of matching materials to the needs of our clients. We are able to adopt various approaches to meet varying client needs. What’s more is that we have more than 40 years of experience to draw upon.

Our Work